Recent Factory Life

Photos from the 1990’s.

A view into the daily work life at Chicago Embroidery Company. We operated two factories with over 90 employees running three shifts. Our emblems were made using Swiss Schiffely looms with a few German made looms.

The Chicago Embroidery Company thanks Gloria P. Chavero-Steedman for taking and saving theses photos.

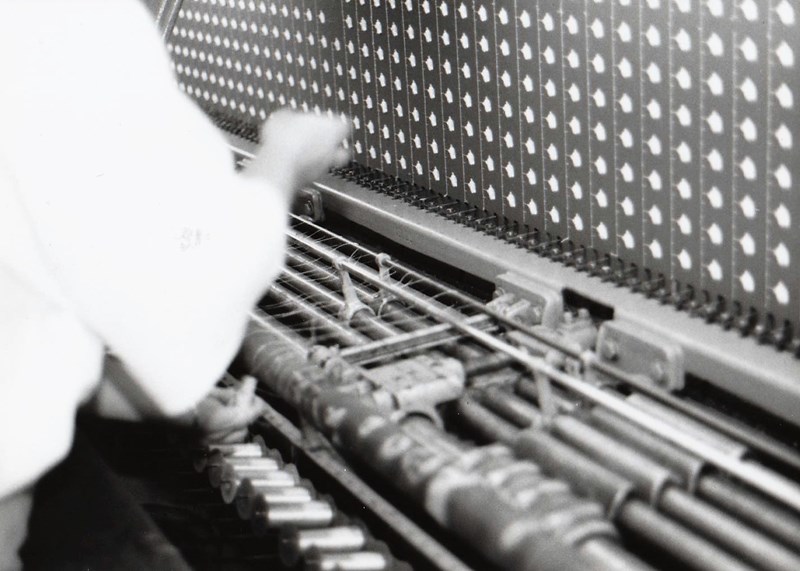

Workers changing out a thread color one of our Schiffley looms.

Factory worker watching over the loom's needles as they stitch the patches.

Factory worker maintaining the loom's mechanical parts.

Worker rethreading the needle when thread slipped out.

Worker threading each needle with the next thread color used in the patch's design.

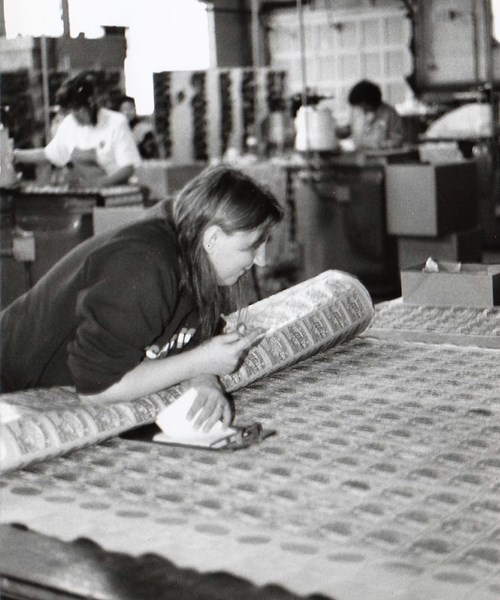

Supervisor inspecting patches for quality after they come off the heat seal machine.

Worker as a watcher, making sure the needles are stitching properly and looking for thread breaks.

Workers die cutting patches after the backing has been placed and inspected

Die cutter uses different dies to cut out each patch. Note the selection of die shapes next to the cutter.

Worker in the merrowing department. Each patch with a merrowed edge was merrowed by hand.

Worker using a merrow machine to add a border to each patch.

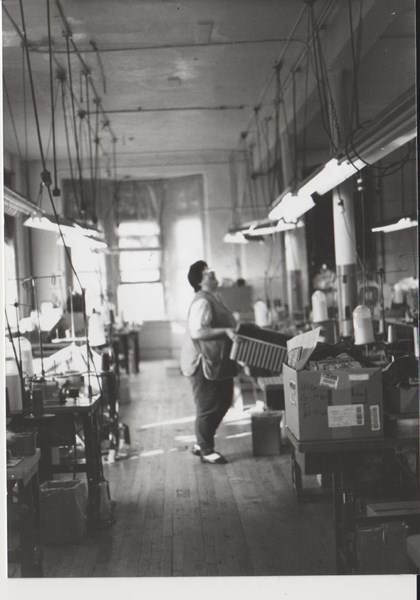

Worker counting and packing patches for shipping.

At the end of the day, a worker in the merrowing, finishing, and shipping department.

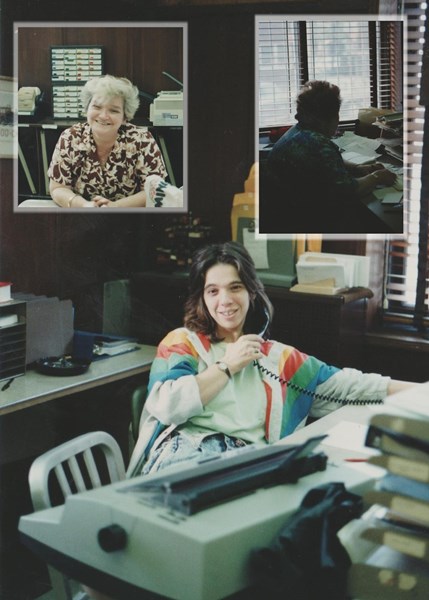

Where orders start and end. Some of the office workers taking customer orders, starting the manufacturing process, and invoicing.